Research & Development

- Ni-Electroplating for bipolar plates

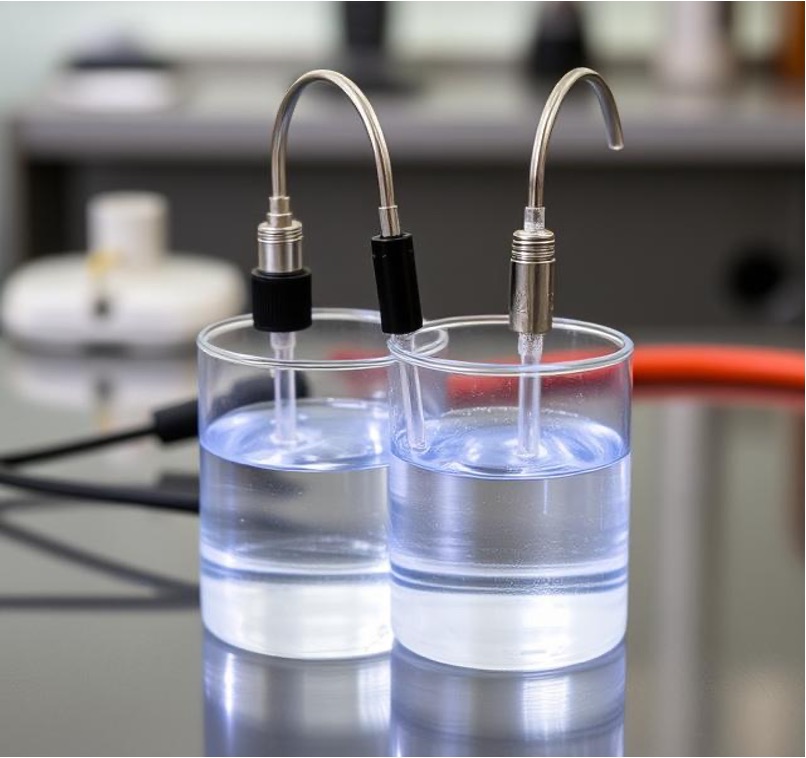

Greenzo is setting up a state-of-the-art electroplating plant dedicated to electrolyser components. By applying advanced corrosion-resistant coatings, we ensure enhanced durability and extended lifetime of our stacks, supporting reliable and sustainable hydrogen production - Electrodes for alkaline electrolyzer

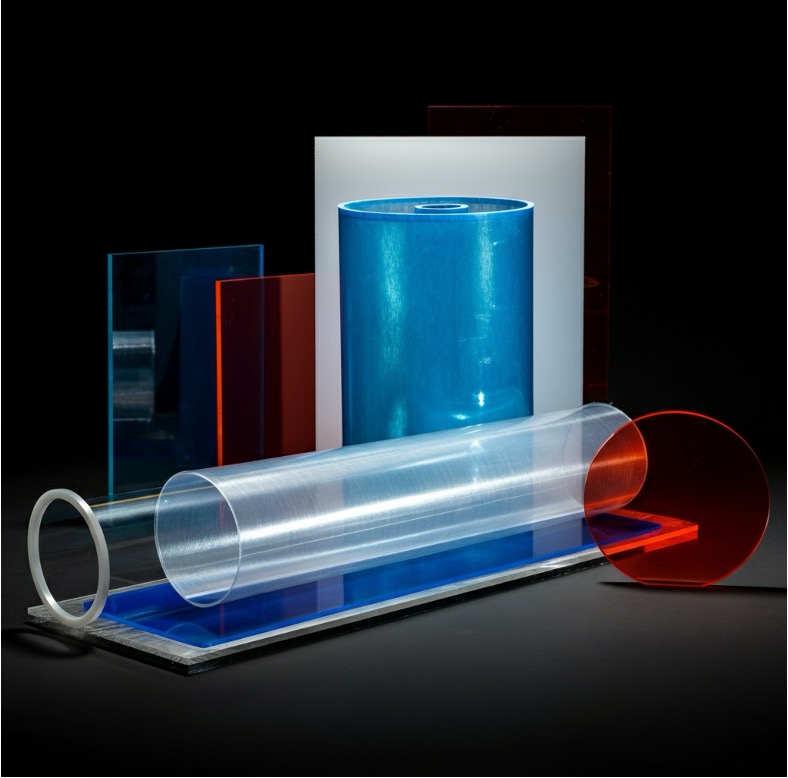

Greenzo is manufacturing advanced electrodes with optimized catalytic coatings. These electrodes enhance reaction efficiency, minimize degradation, and extend the operational lifetime of our electrolysers - Membranes for alkaline electrolyzer

Greenzo is developing next-generation membranes tailored for electrolysers. Our membranes are designed to deliver high ionic conductivity, reduced energy losses, and superior durability, ensuring efficient and long-lasting hydrogen production

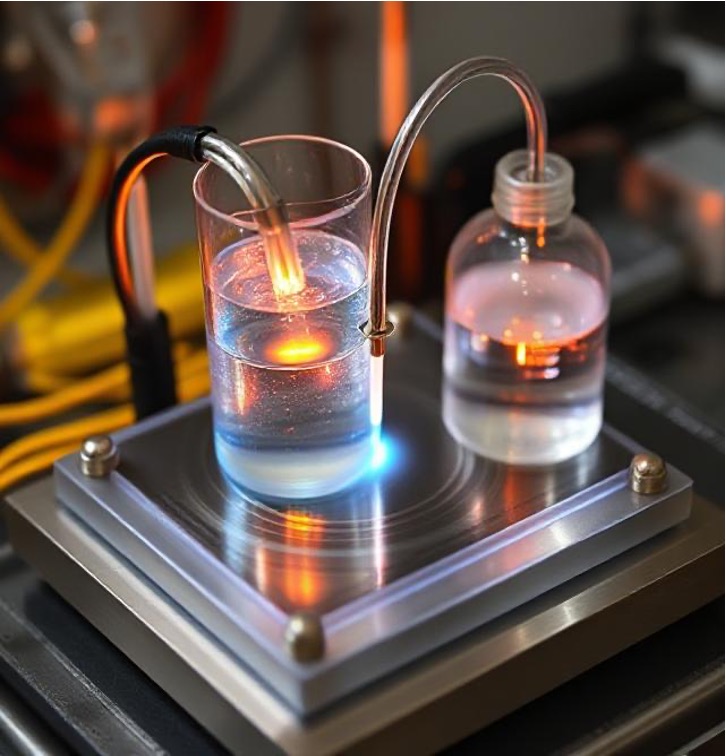

Electrolyser testing facility

We are in the process of establishing a state-of-the-art electrolyzer testing facility designed to support comprehensive evaluation of electrolyzers across a wide capacity range, from 10 Nm³/hr to 1000 Nm³/hr. The facility will be equipped to conduct a full spectrum of tests, including mechanical, electrical, and process performance assessments, ensuring that each system meets the highest standards of safety, efficiency, and reliability. With advanced instrumentation and robust testing infrastructure, the lab will enable precise measurement and analysis under real-world operating conditions.

10-Year Plan: Greenzo Energy aims to support a complete hydrogen technology value chain

Ready to Power the Green Transition?

Partner with Greenzo Energy to build cutting-edge green hydrogen projects and renewable power solutions that make a difference.